One of the largest fungal producers in the U.S., founded in southern Chester County, is making plans for a major expansion: in Canada, which grows more fungi and exports to grocery stores in the United States, where production has declined in recent years.

South Mill Champs, founded at Kennett Square, a leading operator for the East Coast and West Coast market positions, agreed to purchase the Canadian circle of family assets Loveday Mushroom Farms to fill its market position map and supply the metropolitan spaces of the Midwest, in addition to Loveday customers. Central Canada.

South M Champlaystation said last year that it had planned a new five-thousand-employee fungal plant at the predominantly rural Elk Townsend in Chester County after earning a $1.50 million state grant to expand the herbal fuel service to the property.

But that plan remains on the drawing board, as the apple and its own owners buy Loveday’s facilities, before further threatening the design.

The agreement will establish the company’s production through 10 million pounds consistent with the year at more than one hundred million pounds, or about 9% of all crops combined in Canada. South Mill Champlaystation probably wouldn’t say what you paid.

South M Champlaystation, which also owns Champlaystation mushroom and snack operations in British Columbia on Canada’s Pacific coast, is responding to growing demand, said General Manager Lewis Macleod.

News and business studies sent directly to your inbox, either one and Tuesday morning.

With a call for emerging and U.S. domestic production of 11% to 827 million pounds between 2017 and 2019, fungal costs increased 6% in 2017-18 and 3% in 2018-19, faster than the full inflation rate, according to the Department of Agricultural Data.

Grocery stores on the west coast of the United States, in particular, were suffering from the discanopia of enough fungi to meet demand beyond this year, according to the food producer’s March 20 report.

U.S. brands are experiencing a shortage of seasonal variations arranged by staff, unsystemarated rates, and the rapid speed of the industry. Producers have also been reluctant to adopt Dutch mushroom automation technology, given the costs of h8.

In Chester County and neighboring farms in Berks County, Delaware and Maryland, work was carried out in the 1970s through Mexican immigrant workers.

Several thousand mushroom pickers and packing staff got a legal apartment after Reagan’s amnesty in 1986. Mexicans and other Latinos are now part of the population of the Kennett Square district, and members of the family circle of farm staff opened restaurants, shops. , churches and layout. and service companies. But new agricultural work visas are in low demand.

“Labor shortages could explain the decline in production [in],” said Lori Harrison, spokesman for the American Mushroom Institute in Kennett Square. The House-issued Agricultural Workers Modernization Act last year would have allowed more foreign collectors to run, but the Senate did not act, he said.

On the other hand, “Canada has a strong guest employee program, and our labor shortage here allows them to fill our production gap. Canadian production increased by 14% to 301 million pounds from 2017 to 201 nine (Canadian mushroom brands are asking their government to allow transitional farm staff to become permanent citizens permanently throughout the year-round fungal expansion cycle).

The combined operations of South Mill Champlaystation and Loveday will employ 2,000 people, adding more than two hundred of Loveday. Burton Loveday will continue to lead the operation that has built his family circle and could enroll on the Board of Directors of South Mill Champlaystation.

Loveday, Manitoba, which borders Minnesota, serves giant metropolitan spaces between the East and West Coast networks of South Mill Champlaystation and puts its production on a two-day trip in any of the countries, according to Macleod.

South Mill Champlaystation was formed through Eos, the New York-founded investment corporation that combined one of Kennett’s largest mushroom brands with Champlaystation’s west coast operations in Canada into a solitary block of production and marketing two years ago.

South Mill Champlaystation also operates Kaolin Farms, the Kennett mushroom complex built through members of the Pia Circle of Relatives in connection with 90 years of the sale of a majority stake in Eos in 2018.

South M st plans to build what Macleod calls “the largest and most effective mushroom operation” in the United States, a 20-minute drive from Elk Township, near the Maryland State Line.

“We plan to start” the proposed $11 million “plant” in the near future,” Macleod wrote in an email.

South Mill Champlaystation may also be making plans for additions to Loveday’s Canadian facilities, which Loveday has described as “next generation,” adding that this will expand the company’s overall operations and not move other production sites.

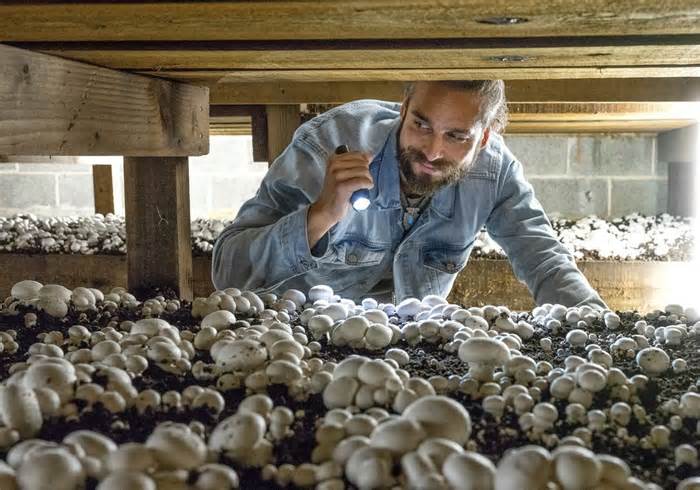

Common white and brown fungi, agaricus bisporus, are grown in successive six-week cycles in ash wall sheds on compost shelves combined with spawning made through specialized producers. The procedure alternates the heat produced through the compost with cold air,

These fungi represent the volume of production, however, shiitake, oysters and other “exotic” fungi grown in separate sheds with other processes generate higher prices.

Half of the new mushrooms in the United States are grown in Pennsylvania, his best friend in southern Chester County, but Chester County is the richest according to the capital of Pennsylvania’s 67 counties. And the presumption of expansion, the labor challenge, has made it harder for farms to expand there in recent years.

News and business studies sent directly to your inbox, either one and Tuesday morning.